3MM Farm Animal Pellet Mill Chicken Duck Feed Pellet Mill Machine 220V Heavyduty

$1,300

3MM Farm Animal Pellet Mill Chicken Duck Feed Pellet Mill Machine 220V Heavyduty

$1,300

- Description

- Additional information

Description

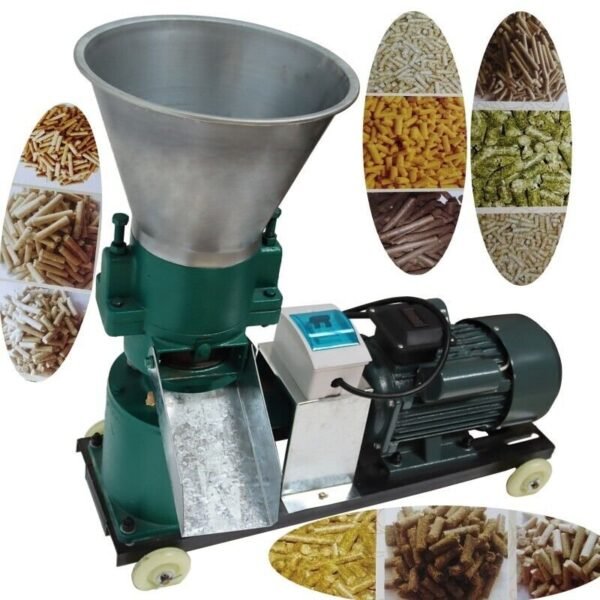

Chicken Feed Pellet Mill Machine 220V 3KW 4HP

3MM Farm Animal Pellet Mill Chicken Duck Feed Pellet Mill Machine 220V Heavy-duty 150KG/H

Thickened Metal Machine Body

Parameter:

- Voltage: 220V

- Motor power: 3KW/4HP

- Production capacity: 150kg/h

- Weight: 231 lbs

- Package Dimension: 36.81*17.13*29.53 inches

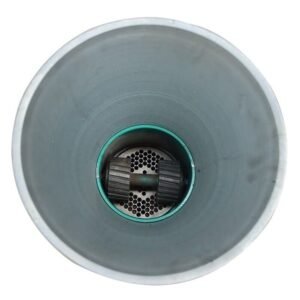

- Grinding plate hole diameter: 3MM

- Application scope of grinding plate:

- 2mm is suitable for parrot, thrush, sparrow, indigo and other pet birds.

- 2.5mm is suitable for small birds and fish.

- 3mm is suitable for baby rabbits, baby chickens, baby ducks, pigeons, grass carp and other small animals.

- 4mm is suitable for adult rabbits, chickens, ducks, geese, pigeons, peacocks, etc.

- 6mm is suitable for pigs, cattle, sheep, dogs, etc.

- 8mm is suitable for fishing lures, large birds, large animals, etc.

Precautions

1.When using, it should be noted that there should be no foreign matter such as stones and ironblocks in the raw materials. After the pellet machine has been working continuously for morethan ten shifts, the pressure roller oil hole, the universal joint oil hole, and the linkage shaft oilhole need to be filled with high-temperature lubricating grease to make the pressure roller Goodworking performance and extended bearing life.

2.During granulation, it is strictly forbidden for the pressure roller to contact with the templateto run idly, and the continuous feeding can not be interrupted.At the same time, the pressureroller shaft nut is locked to avoid loosening and damaging the spindle keyway.

3.When granulating, there is no granulation, no discharge, the template should be removed, andafter opening one by one, some fiber feed can be added appropriately to restart the granulation.

4.Always check the tightness of the screws in each part of the machine. If there is oil leakage inthe gearbox, replace the oil seals in time, and check whether the bearings in the machine headare short of oil.

5.When the pellet machine is working, do not reach into the feeding port with your hands. Ifnecessary, use wooden sticks to help feed the pellets.

6.Before turning on the machine, it is necessary to add less material before turning on the

machine. When shutting down, leave a small amount of feed in the machine to prevent the pressroller of the machine from contacting the template from idling.

7.If the machine is stuck in operation, stop it immediately, press the pressure roller until thebolt is flat,and then restart the machine.

8.Each time the work is completed, the adjusting pressure roller bolts must be loosened.

Details

Usage and specification:

1: It applies to chicken industry.

2:Corn particles can be put into the machine directly. The feed processed by the machine is smooth and has moderate hardness. The temperature-change during the process is slight so the nutrition can be contained very well.

3:The practical’s diameter of the holes can be divided into: Φ2, Φ2.5, Φ3, Φ3.5, Φ4, Φ5, Φ6, Φ7, Φ8, ,Φ10,Φ12.

4:The microorganism and parasite can be killed during the process by extrusion.

Operation: 1: Add oil into gearbox before start.

2:Double-check the belt and the screws before operation.

3:Clean up the rest after use to prevent damage to the machine.

Notice: 1: Iron or stones cannot be put into the griller.

Notice: 1: Iron or stones cannot be put into the griller.

2:Check the elasticity of the belt, and the bearing frequently. Add oil in time when it needs to.

Additional information

| voltage | us-220v |

|---|---|

| Model | pellet-mill |

| mpn | 239df195 |

Related Products

-

Agriculture & Farming, Fence

40x300cm Plastic Chicken Wire Fence Mesh Hexagonal Fencing Wire for Gardening

$38 – $39Price range: $38 through $390 out of 5There is no AI review summary.Select options This product has multiple variants. The options may be chosen on the product pageQuick View -

Agriculture & Farming, Fence

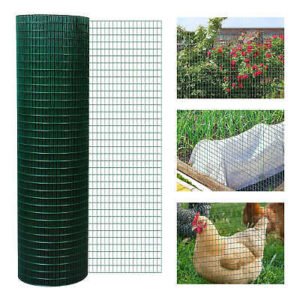

Fencer Wire Vinyl Coated 16 Gauge Welded Fence Wire Roll

$860 out of 5There is no AI review summary.Select options This product has multiple variants. The options may be chosen on the product pageQuick View -

Agriculture & Farming, Fence

Green Welded Hardware Cloth Welded Wire Mesh Chicken Wire Poultry Fence Outdoor

$520 out of 5There is no AI review summary. -

Agriculture & Farming, Fence

Hardware Cloth Wire Mesh Fence Netting Roll for Aviary Chicken Coop Garden

$1230 out of 5There is no AI review summary. -

Agriculture & Farming

VEVOR 6PCS Torpedo Level Set 10/16/24/32/48/78″ Bubble Spirit Level

$930 out of 5There is no AI review summary.